The CBS Advantage

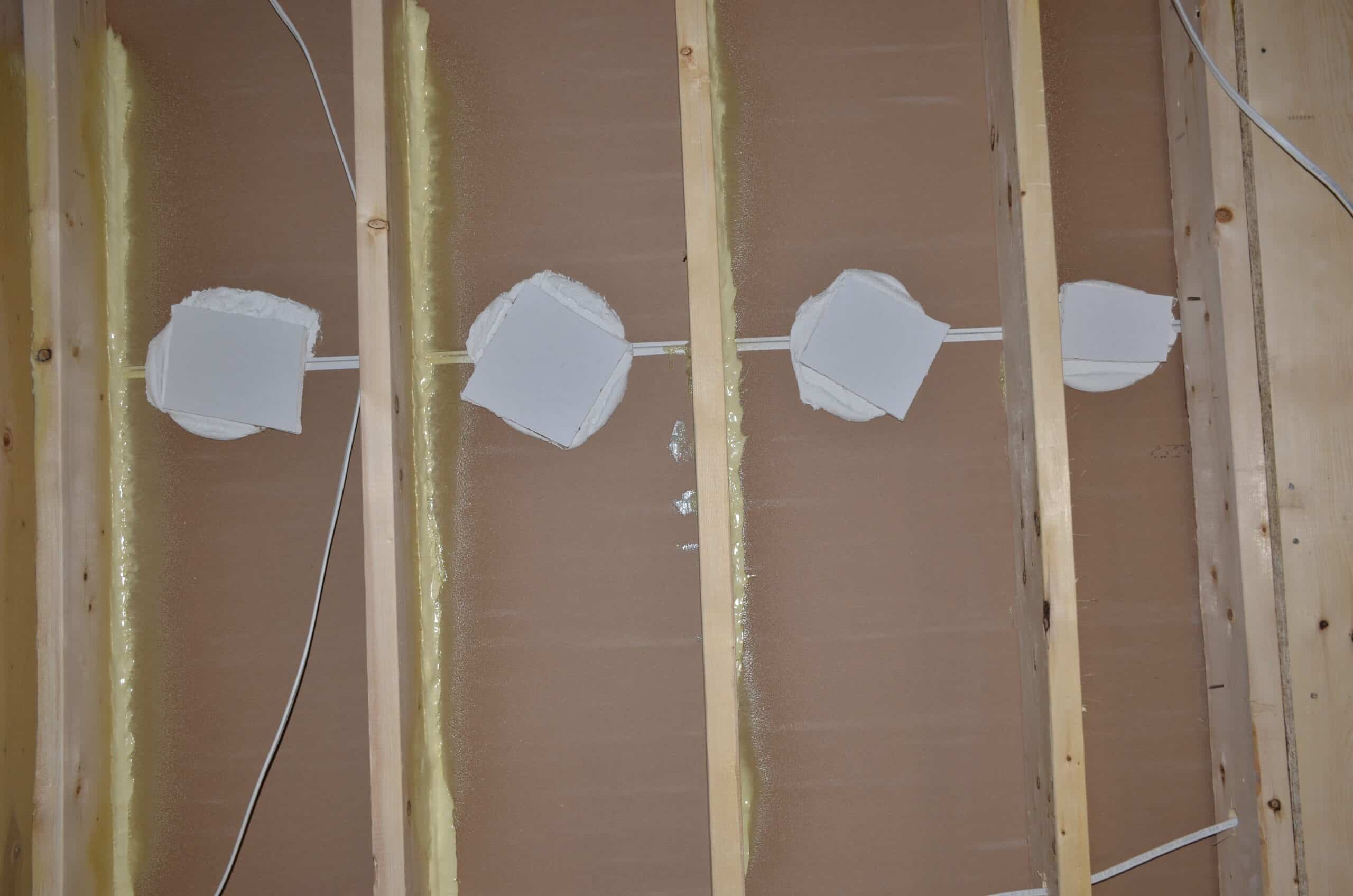

After the home is set and the finishing touches are complete, it is easy to see the quality and craftsmanship of a Custom Building Systems modular home. Take a look inside at the important “hidden” manufacturing details that sets CBS apart from other modular home manufacturers.